Obsnap Instruments Sdn Bhd

29A, Jalan SS 15/4C, 47500 Subang Jaya, Selangor, Malaysia.

Latest News

Lunch in the office is a lunch celebration for the business achievement by Victor

Mar 31, 2016

Samson Chong as a co-founder was sharing with us his appreciation for the wonderful team work for the motivating growth in material testing equipment business both Malaysia as well as in oversea market.

Honda Malaysia Sdn Bhd

Mar 31, 2016

The Requirements:

Solution:

Customer’s Feedback:

Testimonial video

Grill Tech Sdn Bhd

Mar 31, 2016

Customer’s Feedback:

.jpg)

MERIDIAN Salt Spray Corrosion Machine Video

.jpg)

Infra Segi Sdn Bhd Vibration Meter

Mar 31, 2016

Case Study : WSA Engineering Sdn. Bhd

Mar 30, 2016

Chamber with infrared lamps used for test on products surface temperature

Meridian Walk In - Temperature and Humidity Chamber Video

.jpg)

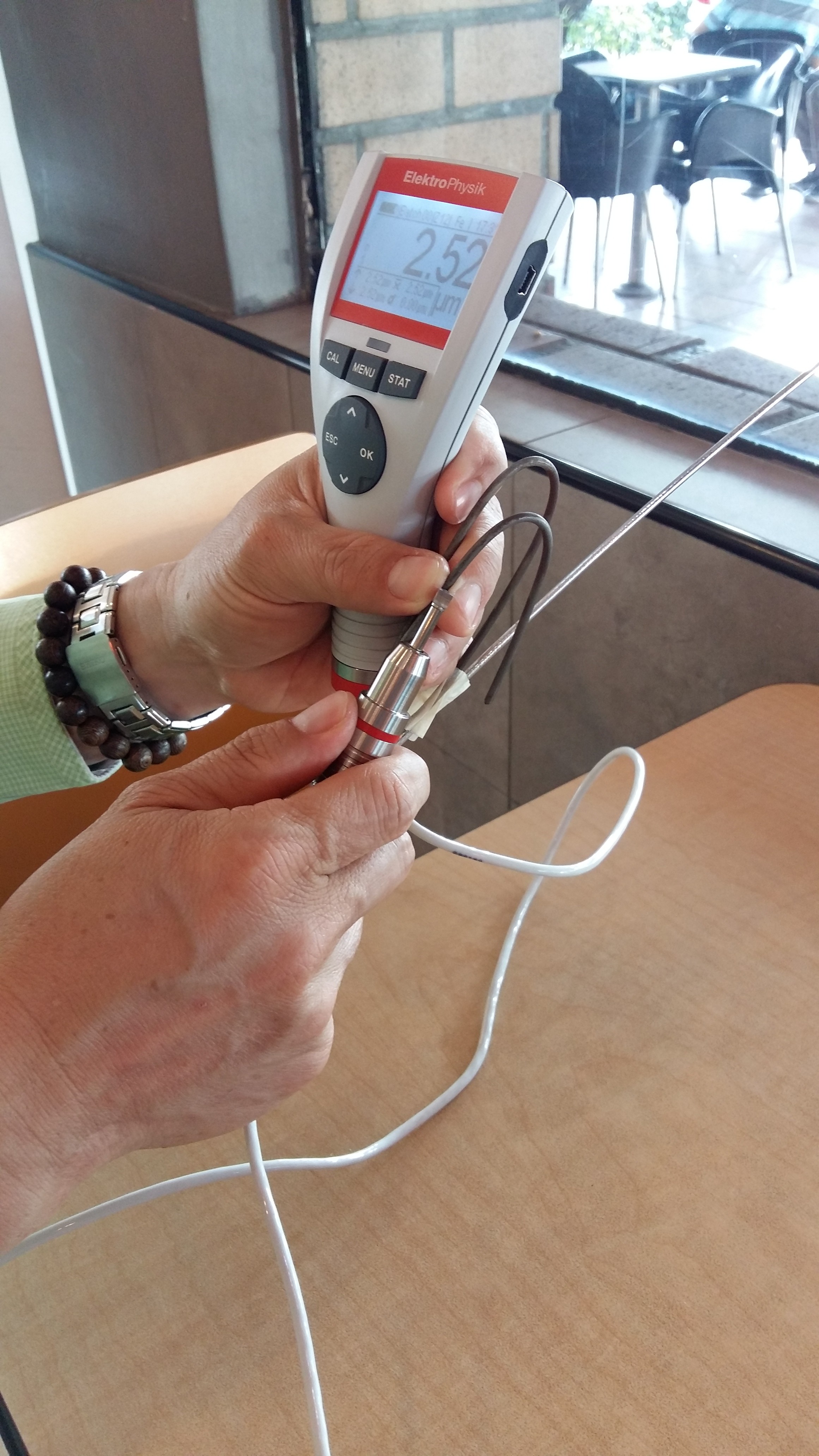

How to measure the zinc coating thickness on a steel wire of 3mm diameter

Mar 29, 2016

How to measure the zinc coating thickness on a steel wire of 3mm diameter

Obsnap product specialist used an Elektrophysik Coating Thickness Gauge model: MiniTest 735 F05M-90. Firstly, we calibrate the coating Thickness Gauge MiniTest 735 F05M-90 by performing zeroing on the uncoated 3mm steel wire, and then followed by calibrate on 1st and 2nd thickness standards. We then store the calibration setting into the Batch memory for easy and accurate measurement whenever we need to measure on this 3mm diameter wire.

The gauge was then ready to take coating thickness measurement precisely to 0.75% accuracy. As you can see, the zinc coating thickness measurement on steel wire were at 32.55 and 33.05 microns.

.jpg)

.jpg)

Solid Component Manufacturing Sdn Bhd is very pleased with the accuracy and durability of ElectroPhy

Mar 23, 2016

How to Protect Your Money Making Production Machinery from Disruption & Damages

Mar 22, 2016

- The risk of not getting 100% purity of raw material into production machine.

- How a precisely matched implementation of proven Sesotec metal detection system in Plastics industry, can save a production cost of RM 100,000 or more annually?

- How Sesotec metal detectors and separator to prevent plug up of hot nozzle, resulting in perfect filling of moulds and ensure quality of products.

- The latest detection technology from Germany for automotive, medical technology, electronics, telecommunication and household appliance industries.

Event Details:

Event code: JS-02-19042016

Date: 19/4/2016(Tuesday)

Time: 1.30pm - 4.30pm

Venue: SIRIM OAS International Sdn Bhd

1, Persiaran Dato’ Menteri, Section 2,

40700 Shah Alam, Selangor.

* Refreshment & Lunch are provided to all participants

* 2 Technical Posters worth RM120 are given out to each company

* Seats are limited, Kindly confirm the no of person to attend by

returning email the latest by 5/4/2016

Normal Seminar fees is RM 298.

It is RM 98 Now!!

Event jointly organized by Sesotec, an established German metal detection system manufacturer with JS Analytical, a specialized solution provider for testing equipment

5 Improvements in Surface Finishes that will Help Increase The Profit

Mar 22, 2016

- What are the 5 most important surface finishes quality that must be controlled to improve productivity

- Why the knowledge of colour matching is important, and critical factors that affect accuracy of colour judgement

- What is Delta E, L, a, b? How it can help to reduce the rejection due to colour mismatch in your parts?

- The characteristic of Metallic paints and how to match the colour?

- How to conduct an overall and complete surface finish evaluations ?

- The industries issue on surface appearance, and solution available to minimise it or eliminate it.

- Overview of latest coating & surface finishes testing technology.

Event Details:

Event code: JS-01-19042016

Date: 19/4/2016(Tuesday)

Time: 9am – 12pm

Venue: SIRIM OAS International Sdn Bhd

1, Persiaran Dato’ Menteri, Section 2,

40700 Shah Alam, Selangor.

* Refreshment & Lunch are provided to all participants

* 2 Technical Posters worth RM120 are given out to each company

* Seats are limited, Kindly confirm the no of person to attend by

returning email the latest by 5/4/2016

Normal Seminar fees is RM 298.

It is RM 98 Now!!

Event jointly organized by X-rite , world leader in spectrophotometer for colour matching, QC and formulation and JS Analytical, a specialized solution provider for testing equipment. Rhopoint Instruments’ range of intelligent glossmeters that can measure Haze, DOI on orange peel are part of the discussion topic.

Norwards is a manufacturer and supplier for ductile iron pipes and fittings

Mar 22, 2016

Customer from one of the Top 10 Paint Manufacturer using Xrite Ci7600

Mar 21, 2016

Customer from one of the World leading paint manufacturer established over 200 years with 2014 total sales of US$132.3 billion, ranked among the Top 10 ,is using best-in-class performance in the lab, an Xrite Ci7600 Benchtop Spectrophotometer for paint quality control and colour matching. Joe Yen, our product manager has just commissioned and provided a comprehensive training which include colour theory and hands-on application of the X-rite Benchtop Spectrophotometer Ci7600.

HACCP Graded Food Safety is Achieved Through JS Analytical

Mar 17, 2016

.jpg) In-line free fall metal detector installed in a food production line Sesotec Rapid 5000

In-line free fall metal detector installed in a food production line Sesotec Rapid 5000Repair and Calibration of Barcol Hardness Tester

Mar 14, 2016

Barcol Impressor GYZJ-934-001 being repaired for almost a half day even though the usage of this instrument is straight forward

A thorough inspection of the internal mechanism parts is being carried out by our service technician

Paint Inspection Kit

Mar 11, 2016

Obsnap Paint Inspection Kit that comprised of coating thickness gauge, wet film thickness gauge ,surface profile gauge, thermometer, and whirling hygrometer.

It is a customised kit prepared for our customer's on-site inspection job.

Visitor from Jetro and Hirokazu Japan Manufacturers

Feb 22, 2016

.png)

Having business meeting about Digital Mined Pipe Locator with Jetro and Hirokazu Japan Manufacturers

To Ensure Colour Accuracy on 5 Unusual Surface

Jan 27, 2016

|

|||||||||||||||||

|

|||||||||||||||||

|

|||||||||||||||||

|

|||||||||||||||||

|

|||||||||||||||||

Product launch - Coating Thickness Gauge - MiniTest 725-735-745

Jan 21, 2016

|

|

|

|

|

|

|

|

|

|

.JPG)